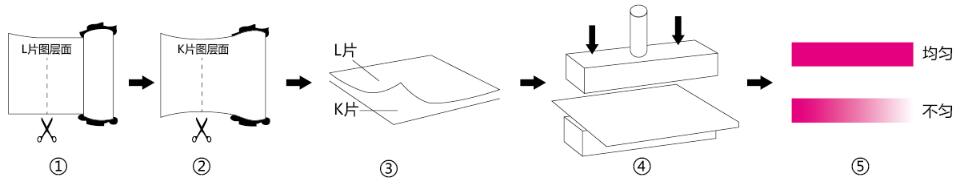

Prepare the L-Sheet

Cut the L-sheet (from the black bag, coating side inward) into the desired shape.

Prepare the K-Sheet

Cut the K-sheet (from the blue bag, coating side outward) into the desired shape.

Assemble the Test Film

Place the L-sheet and K-sheet together with their coated sides facing each other gently.

Insert the Test Film

Insert the assembled pressure test film between the surfaces where pressure measurement is required.

Observe the Developed K-Sheet

After testing, remove the pressure test film.

Place the developed K-sheet with the smooth PET side facing up on a white sheet of paper.

Observe in a well-lit area. By visually inspecting the color density and uniformity, the pressure distribution can be determined.

For quantitative pressure measurement, refer to the standard pressure-density curve to determine the pressure value.

Standard Pressurization Conditions for Pressure Test Film

Sustained Pressure

Gradually increase the applied pressure. Reach the target pressure in 2 minutes, and maintain the pressure for 2 minutes.

Instantaneous Pressure

Gradually increase the applied pressure. Reach the target pressure in 5 seconds, and maintain the pressure for 5 seconds.

SaiYon

电话微信:13328020789

©SaiYon Sitemap