This article introduces the LLLW Prescale Film, also known as the 3LW Pressure Measurement Film. Both names refer to the same product model.

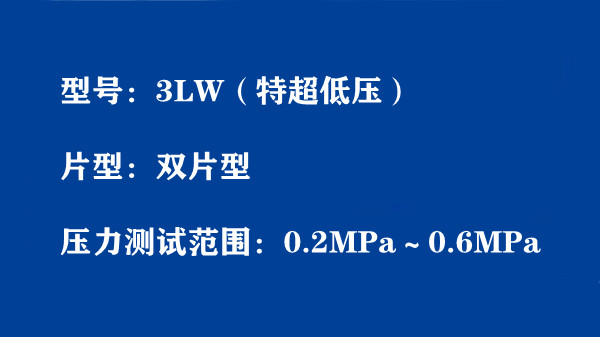

The LLLW (3LW) Prescale Film is a super ultra-low pressure, two-sheet type pressure measurement film designed for precise and sensitive contact pressure visualization.

Pressure Range: 0.2 MPa – 0.6 MPa

Film Dimensions: 270 mm × 5 m

These two specifications summarize the product clearly. In most cases, the LLLW type is commonly referred to as 3LW, as this naming convention is easier to distinguish and reduces the chance of confusion in communication or documentation.

The 3LW Prescale Film is widely used in the optoelectronic and smartphone manufacturing industries. As new product designs emerge, the performance requirements for the 3LW type have become increasingly stringent. For example, many modern applications now require the film to withstand operating temperatures exceeding 200°C.

Usage Precautions

During Pressure Application:

The L film is highly sensitive and reacts to even slight pressure. Handle carefully before use — do not press, rub, or fold the film.

The color-developing microcapsules inside may adhere to the skin; prolonged contact may cause skin irritation in sensitive users. It is recommended to wear gloves during handling.

Recommended working environment: 20°C–35°C, 35%RH–80%RH. Operating outside these conditions may affect measurement accuracy.

The developed color intensity of the K film may vary depending on temperature, humidity, and applied pressure conditions.

If the coated surfaces of the L or K film are contaminated with water, oil, or other substances, color development may fail. Ensure the test area is clean before use.

In high-temperature, long-duration pressing, add insulating material on the film’s outer side to prevent heat impact.

In wet or oily environments, seal the sample in a waterproof and oilproof bag before pressing to prevent direct contact and color interference.

Used Prescale films cannot be reused.

Please use within the shelf life indicated on the packaging.

Measurement Phase

It is recommended to measure color density within 30–60 minutes after pressure application. During this period, the color density will first gradually increase and then slowly fade. Measuring within this window ensures the most accurate and consistent results.

SaiYon

电话微信:13328020789

©SaiYon Sitemap