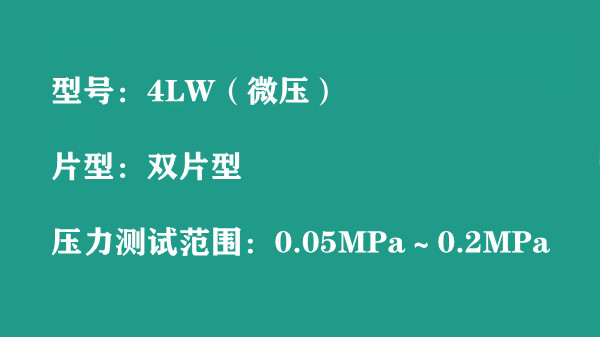

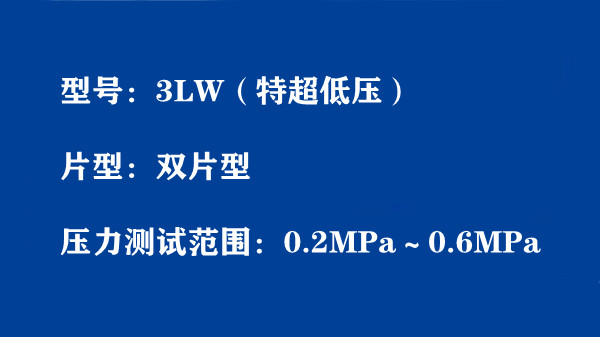

Product Information

Model: 2LW (ultra-low voltage)

Sheet type: Double sheet type

Pressure testing range: 0.5MPa~2.5MPa

Shelf life: 2 years

Function: This product can characterize the distribution of pressure by the uniformity of color;

The color density value can directly characterize the corresponding pressure value.

Product features

(1) Convenient and intuitive inspection of the distribution and uniformity of applied pressure.

(2) Different color densities correspond to the magnitude of applied pressure, and the

pressure value can be determined through the standard pressure density curve. (3) Fast

measurement speed, clear and intuitive image after pressing.

Product features

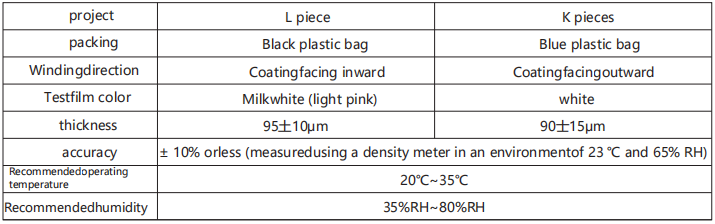

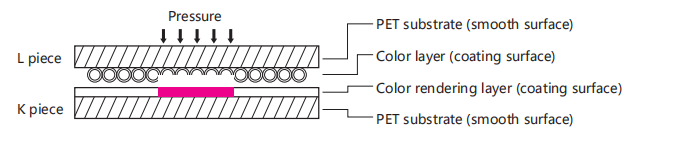

Product structure and working principle

Stick the coating surface of L sheet together with the coating surface of K sheet. After applying pressure, the microcapsules carrying the color substance on the L plate ruptured, and the color substance reacted chemically with the corresponding K plate chromogenic agent, presenting a red color. The degree of microcapsule rupture is determined by the amount of pressure applied. The higher the pressure, the more microcapsules are damaged, and the higher the color density. On the contrary, the lower the hair color density.

Standard Pressurization Conditions

- Continuous Pressurization: Gradually increase pressure over 5 seconds until the set pressure value is reached, then maintain the pressure for 2 minutes.

- Instantaneous Pressure: Gradually increase pressure over 5 seconds until the set pressure value is reached, then maintain the pressure for 5 seconds.

Pressure Distribution and Pressure Value Measurement Methods

Pressure Distribution Using Pressure Test Film

Based on the changes in pressure, the red density of the film changes. The deeper the red color, the higher the pressure; the lighter the red color, the lower the pressure. When observing, place the colored K-film with the glossy PET side facing up on a white piece of paper in a well-lit area.

Using Pressure Test Film with Standard Pressure Density Curve

To determine a specific pressure value, refer to the standard color sample of the pressure test film and the standard pressure density curve. By considering the temperature and humidity conditions during pressurization and the pressurization type (continuous or instantaneous), you can select the appropriate standard pressure density curve to determine the pressure value. When observing, place the colored K-film with the glossy PET side facing up on a white piece of paper in a well-lit area.

Precautions

Pressurization Stage:

- The L-film responds very sensitively to slight pressure, so avoid pressing or rubbing it before use. Handle with care.

- The coloring material inside the microcapsules may transfer to your hands. Prolonged contact may cause skin irritation in sensitive individuals. It is recommended to wear gloves during handling.

- The recommended operating conditions are 20°C to 35°C, with a relative humidity of 35% RH to 80% RH. Using outside these conditions may affect the accuracy of pressure measurements.

- The color of the K-film may change after pressurization due to factors such as temperature, humidity, and pressurization conditions.

- If there are any foreign substances, such as water or oil, on the coating surface of the L-film or K-film, it may not show proper color. Be sure to clean the measurement surface before use.

- Special environmental use:

a. For long-term high-temperature pressurization, add heat-insulating material on the outside of the film to ensure the sample is not affected by temperature.

b. In water or oil environments, place the sample inside a waterproof, oil-resistant bag before applying pressure to prevent the sample from coming into contact with water or oil, which could affect the coloring effect.

- Special environmental use:

- Used pressure test films should not be reused.

- Use within the product’s shelf life.

Testing Stage:

It is recommended to measure the color density 30-60 minutes after pressure application. During this time, the color density will gradually increase before slowly decreasing.

Storage Conditions:

Samples will gradually fade over time after coloring, so it is recommended to scan the image for storage.

Avoid placing in direct sunlight or near heat sources. For long-term storage, keep below 15°C and store in a dark environment. Unused L-film and K-film should be placed back in their original packaging (L-film in a black plastic bag, K-film in a blue plastic bag) and stored in the packaging box.

Avoid contact with the following substances during storage: carbonless copy paper, water, oil, solvents, chemicals, plasticizers, plastic products containing plasticizers, rubber, erasers, or oil-based pen marks.

After coloring, store the K-film in a paper bag. When storing multiple K-films together, ensure the colored surfaces do not touch. It is recommended to separate them with white paper.

标准加压条件 持续加压:

施压过程逐渐增加压力,5 秒达到压力设定值,保持压力 2 分钟。

瞬时压力:

施压过程逐渐增加压力,5 秒达到压力设定值,保持压力 5 秒。

压力分布及压力值测定方法

用压力测试膜侧压力分布 根据压力的变化,红色密度发生变化,红色较深的部分,压力较高;红色较浅的部分压力较低。 观察时,将发色后的 K 片光面(PET 面)朝上,放置在白色纸张上,在比较明亮的场所观察。

用压力测试膜与标准压力密度曲线图组合,查找压力值 需要得知一定程度的压力值时,可以通过观察压力测试膜标准色样和标准压力密度曲线图进行 判定。可通过施压时的温湿度条件,加压条件(持续压力、瞬间压力)选择标准压力密度曲线, 从而知道其压力值。观察时,将发色后的 K 片光面(PET 面)朝上,放置在白色纸张上,在比 较明亮的场所观察.

注意事项:

施压阶段:

(1)L 片受到轻微的压力就会有非常敏感的反应,使用前不要按压、摩擦,轻拿轻放。

(2)微胶囊内的成色物质会沾到手上,长时间接触,敏感人群可能引起皮肤过敏,建议佩戴手 套操

(3)推荐使用的环境条件为 20℃~35℃,35%RH~80%RH。超出工作条件范围使用时,会影响压 力测定值的准确性。

(4)使用时因为温度、湿度、加压条件等因素不同,施压后 K 片呈现的颜色会有变化。

(5)L 片和 K 片的涂层面如附着水、油等异物,可能无法正常显示颜色,使用前需清洁测定部 位。特殊环境下使用:a.在长时间高温加压时,应在膜外侧增加隔热材料,确保样品不会受温 度影响;b.在水或油环境下,应将样片放入防水、防油袋中再加压,防止样品与水、油接触, 影响发色效果。(6)使用过的压力测试膜不可再次使用。 (7)请在保质期内使用。

测试阶段: 建议施压显色后 30min-60min 之间进行密度测量。在施压后的时间内,发色密度会先逐渐升高, 然后又慢慢降低。

储存条件:

(1)避免放置在阳光直射、靠近火源的地方。长期储存时,请在 15℃以下避光保存。未使用完 的 L 片、K 片应放回原包装袋中(L 片为黑色塑料袋,K 片为蓝色塑料袋),并放置在包装盒内保 存。

(2)储存过程中避免与如下物质接触:无碳复写纸、水、油、溶剂、化学药品;增塑剂、含增 塑剂塑料制品;橡胶、橡皮;油性笔字迹等。

(3)发色后的 K 片请放于纸袋中保存。多张 K 片一起保存时,保证发色面不要相互接触,建议 中间用白纸隔开。

(4)发色后样片会随储存时间的延长有一定程度的褪色,建议扫描图像储存。

SaiYon

电话微信:13328020789

©SaiYon Sitemap