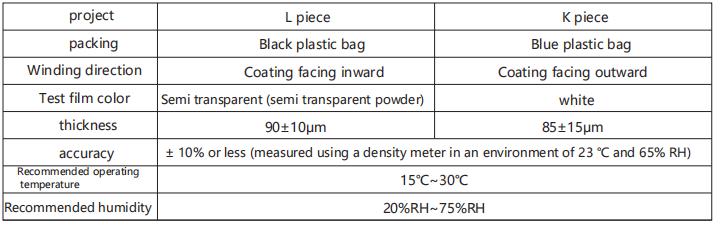

Product Information

Model: 4LW (micro pressure)

Sheet type: Double sheet type

Pressure testing range: 0.05MPa~0.20MPa

Shelf life: 1 year

Function: This product can characterize the distribution of pressure by the uniformity of color;

The color density value can directly characterize the corresponding pressure value.

Product features

(1) Convenient and intuitive inspection of the distribution and uniformity of applied pressure.

(2) Different color densities correspond to the magnitude of applied pressure, and the

pressure value can be determined through the standard pressure density curve.

(3) Fast measurement speed, clear and intuitive image after pressing.

Product features

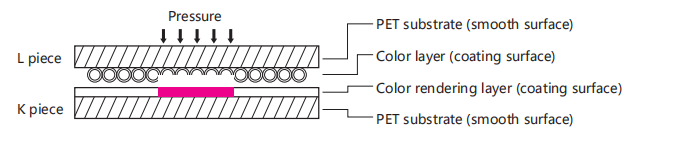

Product structure and working principle

Stick the coating surface of L sheet together with the coating surface of K sheet. After applying pressure, the microcapsules carrying the color substance on the L plate ruptured, and the color substance reacted chemically with the corresponding K plate chromogenic agent, presenting a red color. The degree of microcapsule rupture is determined by the amount of pressure applied. The higher the pressure, the more microcapsules are damaged, and the higher the color density. On the contrary, the lower the hair color density.

Standard Pressurization Conditions

- Continuous Pressurization: Gradually increase pressure over 5 seconds until the set pressure value is reached, then maintain the pressure for 2 minutes.

- Instantaneous Pressure: Gradually increase pressure over 5 seconds until the set pressure value is reached, then maintain the pressure for 5 seconds.

Pressure Distribution and Pressure Value Measurement Methods

Pressure Distribution Using Pressure Test Film

Based on the changes in pressure, the red density of the film changes. The deeper the red color, the higher the pressure; the lighter the red color, the lower the pressure. When observing, place the colored K-film with the glossy PET side facing up on a white piece of paper in a well-lit area.

Using Pressure Test Film with Standard Pressure Density Curve

To determine a specific pressure value, refer to the standard color sample of the pressure test film and the standard pressure density curve. By considering the temperature and humidity conditions during pressurization and the pressurization type (continuous or instantaneous), you can select the appropriate standard pressure density curve to determine the pressure value. When observing, place the colored K-film with the glossy PET side facing up on a white piece of paper in a well-lit area.

Precautions

Pressurization Stage:

- The L-film responds very sensitively to slight pressure, so avoid pressing or rubbing it before use. Handle with care.

- The coloring material inside the microcapsules may transfer to your hands. Prolonged contact may cause skin irritation in sensitive individuals. It is recommended to wear gloves during handling.

- The recommended operating conditions are 20°C to 35°C, with a relative humidity of 35% RH to 80% RH. Using outside these conditions may affect the accuracy of pressure measurements.

- The color of the K-film may change after pressurization due to factors such as temperature, humidity, and pressurization conditions.

- If there are any foreign substances, such as water or oil, on the coating surface of the L-film or K-film, it may not show proper color. Be sure to clean the measurement surface before use.

- Special environmental use:

a. For long-term high-temperature pressurization, add heat-insulating material on the outside of the film to ensure the sample is not affected by temperature.

b. In water or oil environments, place the sample inside a waterproof, oil-resistant bag before applying pressure to prevent the sample from coming into contact with water or oil, which could affect the coloring effect.

- Special environmental use:

- Used pressure test films should not be reused.

- Use within the product’s shelf life.

Testing Stage:

It is recommended to measure the color density 30-60 minutes after pressure application. During this time, the color density will gradually increase before slowly decreasing.

Storage Conditions:

Samples will gradually fade over time after coloring, so it is recommended to scan the image for storage.

Avoid placing in direct sunlight or near heat sources. For long-term storage, keep below 15°C and store in a dark environment. Unused L-film and K-film should be placed back in their original packaging (L-film in a black plastic bag, K-film in a blue plastic bag) and stored in the packaging box.

Avoid contact with the following substances during storage: carbonless copy paper, water, oil, solvents, chemicals, plasticizers, plastic products containing plasticizers, rubber, erasers, or oil-based pen marks.

After coloring, store the K-film in a paper bag. When storing multiple K-films together, ensure the colored surfaces do not touch. It is recommended to separate them with white paper.

SaiYon

电话微信:13328020789

©SaiYon Sitemap