Checking the Pressure Distribution of Engine Cylinder Gaskets

Measurement Method: Place pressure test paper on both sides of the engine cylinder gasket (on the engine body and head). After placing the gasket, close the engine body and head and tighten the bolts. Then, remove the engine body and head and check the pressure test paper for its color change.

Key Check Points: Ensure that the surrounding color shows no significant gaps and the pressure value is within the specified range. The color distribution should be even, both horizontally and vertically.

Recommended Models: High-Pressure (HHS), Pressure (HS), Medium-Pressure (MS/MW)

Brakes

Measurement Method: Place pressure test paper between the brake pads, friction surface, and the drive system, and then operate the brake. After operation, remove the pressure test paper and observe the color change.

Key Check Points: Ensure the contact area is sufficiently large, the pressure distribution is uniform, and the pressure remains above a specified value under slow, normal, and aggressive operation conditions. Also, check the consistency of the contact area and pressure after a specified number of uses (equivalent to running distance).

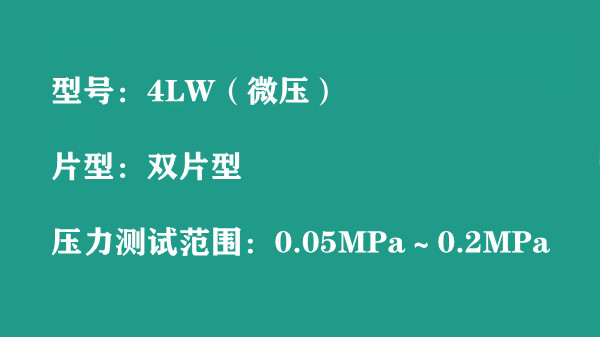

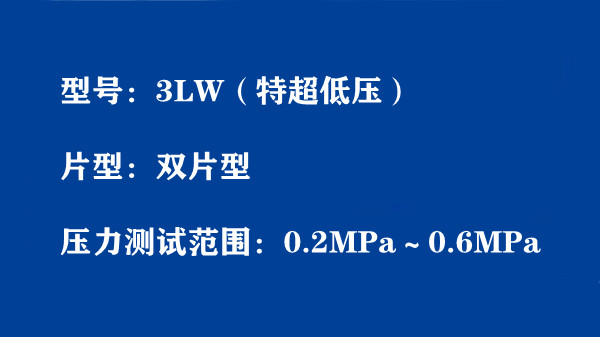

Recommended Models: Low-Pressure (LW), Super-Low-Pressure (LLW)

Carburetor

Measurement Method: Place pressure test paper at the joint of the metal seal, tighten the bolts, and ensure full connection. Then, remove the paper and observe the color change.

Key Check Points: Ensure the color change at the joint is uniform, with the color concentration meeting the specified value. If any part shows lighter color, it indicates uneven pressure, which could lead to deformation or misalignment.

Recommended Models: Medium-Pressure (MW), Low-Pressure (LW), Super-Low-Pressure (LLW)

Oil Pan

Measurement Method: Place pressure test paper at the joint where oil leakage is a concern, tighten the bolts to ensure a complete seal, and then remove the paper and check the color change.

Recommended Models: Low-Pressure (LW), Super-Low-Pressure (LLW)

Clutch

Measurement Method: Place pressure test paper between the clutch plates, operate the clutch, and remove the paper after operation to check the color change.

Key Check Points: Ensure the contact area is sufficiently large, and the pressure is uniformly distributed above a certain value. Check the uniformity of the contact area and pressure after changing the operation speed, and after the specified number of uses.

Recommended Models: Low-Pressure (LW), Super-Low-Pressure (LLW), Ultra-Super-Low-Pressure (LLLW)

Tires

Measurement Method: Place pressure test paper on the ground, place the tire on top, and apply weight. Alternatively, run for a certain distance and then observe the color change of the pressure test paper to check the ground contact pressure.

Key Check Points: Ensure the contact area is sufficiently large, and the pressure is uniformly distributed above a certain value. Check the uniformity of the area and pressure after changing the running speed, bending state, or variations in temperature/humidity.

Recommended Models: Super-Low-Pressure (LLW), Ultra-Super-Low-Pressure (LLLW)

Airbag

Measurement Method: Apply pressure test paper to various parts of a human body model or the vehicle (e.g., front windshield, dashboard) during a collision test. Afterward, the impact pressure on the airbag and body or vehicle parts will be recorded on the test paper, which can be analyzed.

Key Check Points: Confirm the collision area and pressure peak values, and verify the overall weight.

Recommended Models: Super-Low-Pressure (LLW), Ultra-Super-Low-Pressure (LLLW)

Collision Testing

Measurement Method: Place pressure test paper on various parts of the vehicle (e.g., body, dashboard) during collision tests. After the test, check the pressure values on the test paper.

Key Check Points: Confirm the collision area and pressure peak values, and verify the overall weight.

Recommended Models: High-Pressure (HS), Medium-Pressure (MS/MW), Low-Pressure (LW)

Packaging Seal Integrity

Measurement Method: Place pressure test paper on the sealing part of the packaging, apply pressure according to the specified value, and then remove the paper and observe the color change.

Key Check Points: Ensure that the color distribution around the sealing area is uniform and that the pressure value reaches the specified value.

Recommended Models: High-Pressure (HS), Medium-Pressure (MS/MW)

SaiYon

电话微信:13328020789

©SaiYon Sitemap